Twin-Pump Digital Pressurisation Unit with

Low-level Protection, BMS Interface and

second tank for Glycol Top-up

Model: IPP257D/AS

Stock Code: 1198407

The IPP257D/AS is a twin-pump (duty/standby) unit featuring fully-automatic digital control via an integrated panel and 4-20mA pressure transducer.

HMI and BMS interface is provided with configurable outputs including high/low pressure, low-water level, high/low current, voltage, run hours, alarm and pump status. Second tank fitted for automatic top-up of glycol depending on system requirements.

Option: Standard operating pressure is 0.8 to 2.5 Bar. High pressure version available on request with operating pressure of 2.0 to 4.0 Bar (Model: IPP257D/BS, Stock Code: 1195854)

Key Features

- Twin pump unit

- Fully automatic digital control panel

- Low level protection float switch

- Realtime information

- Continuously rated pumps

- Built-in motor protection

- High, low & pump pressure switches with visual setting indicators

- 2 x 25L break tanks c/w lid - 1⁄2” ballcock & polyfloat

- 1” Balancing Valve for Adding Glycol Percentage

- 8L pressure vessel

- Non-return valves on suction & discharge pipework

- Pressure gauge

- Isolating valves

- Maintenance drain valve

- Demountable fittings

- Factory tested

- Set at 1.00 Bar cold fill pressure

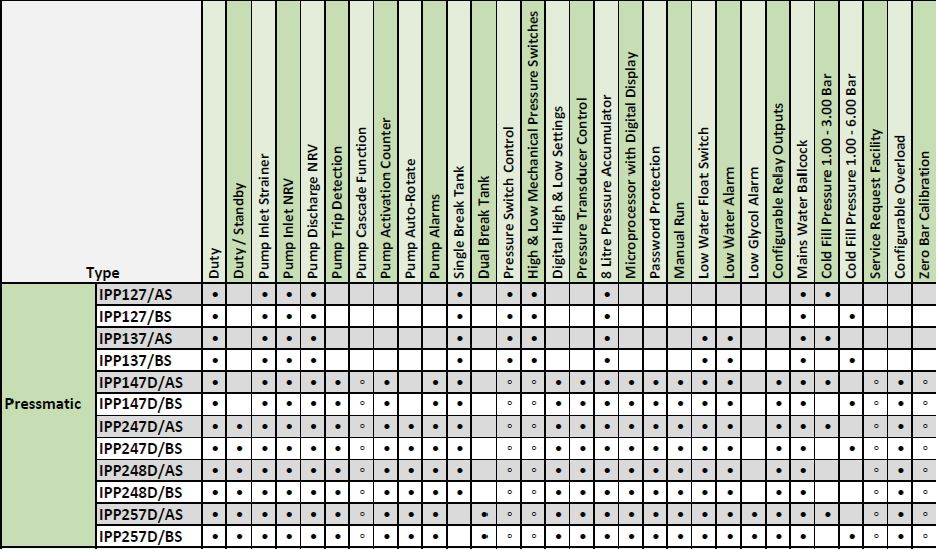

Selection Guide

Specifications

Electrical Details:

230 Volts / 1 Phase / 50 Hz,

0.37 kW, 2.70 Amps FLCDimensions:

0.72 m (l) x 0.35 m (d)

x 0.95 m (h)

Cold Fill Pressure:

50 kPa to 250 kPa

(0.50 kPa – 320kPa is available on request)

Frequently Asked Questions

What does a Pressmatic do?

The Pressmatic re-pressurises the water in any heating or chilled water application. Pressmatics are used wherever there is a need to maintain the fill pressure in both sealed heating and chilled water systems.

What applications does Pressmatic cover?

A solution is available for all installations, from the small ‘retrofit’ market to large commercial and industrial applications.

Installing the correct expansion equipment with Reflex deerators and dirt separators will prevent the sick installation syndrome affecting your project.

How many Pressmatic models are there?

There are six standard options for a pressurisation unit to suit all applications. Selection is based simply on your requirements, i.e. whether you require a basic unit, single pump, twin pump unit with BMS facilities, digital unit etc.

All the pressurisation units featured are designed for installation with our range of Reflex fixed air cushion or Reflexomat variable volume expansion vessels.

Correct selection of the expansion vessels is the key to problem-free system operation and our technical sales staff will be pleased to assist you in expansion vessel selection.

Downloads

Benefits

Suitable for use in heated or chilled applications

Automatically maintains system requirements